Tel: 0086769-23187408

Email: info@linzshoes.com

Tel: 0086769-23187408

Email: info@linzshoes.com

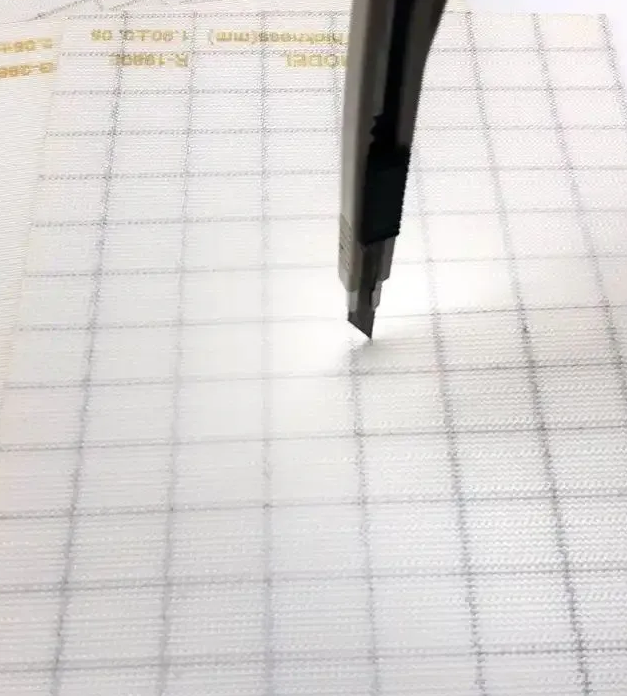

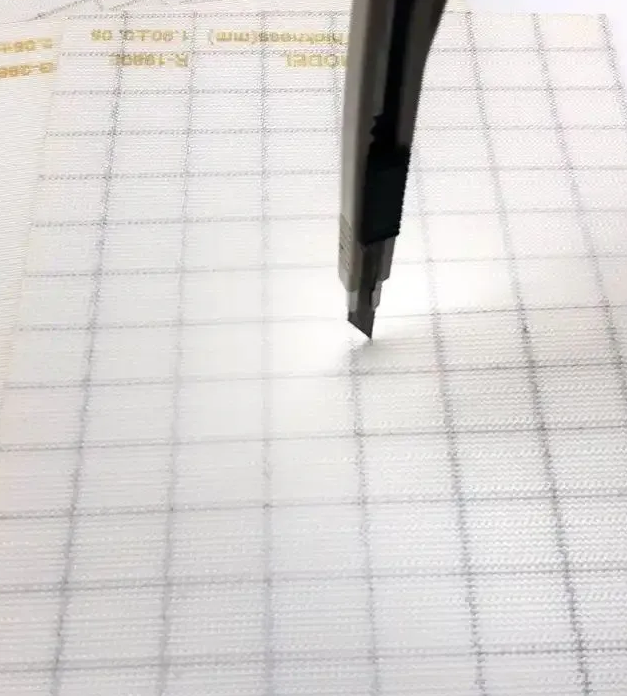

Puncture-resistant fabric ensures optimal protection against puncture hazards while prioritizing your comfort. Its durable construction and advanced technology provide peace of mind and reliable defense against sharp objects, making it ideal for safety gear applications.

Puncture-resistant fabrics offer significant advantages in environments which are high risk, where sharp objects are constantly posing threats. These modern materials bring out performance advantages to enhance safety and protection across industries.

Strong fibers and inventive manufacturing techniques make up puncture-resistant fabrics that can take lots of force or all the pressure from nails, splinters, blades or any other sharp objects in fact. It is this strength that ensures the material does not get damaged even under difficult conditions; thus, its protective ability is still intact.

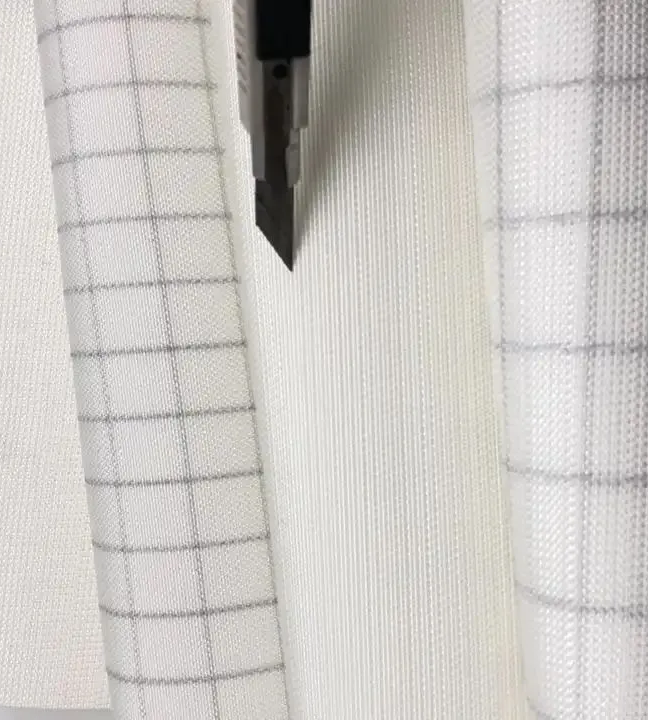

In addition, puncture proof fabric places emphasis on being flexible and comfortable without sacrificing security. They are designed to be light-weight and breathable for easy maneuvering over long periods. This is particularly crucial for professionals like construction workers, police officers or industrial technicians who require quickness and agility in their jobs.

Finally, Puncture resistant fabrics have distinct performance advantages that help minimize injury risks within various sectors. Its exceptional toughness, flexibility as well as dependable shielding qualities mean it is a critical component of your safety gear.

In regard to Hazmat protection, puncture-resistant fabrics are the ones which ensure workers are safe against dangers at risky locations. Because of its outstanding strength and durability, this specialized material acts as a significant barrier against pricks and injuries that are potentially disastrous.

Building and design techniques employed determine how effective puncture resistant textiles will be. Manufacturers use high-performance fibers like aramid, polyethylene or a mixture of several other specialty materials to produce these fabrics. By so doing, they increase the resistance of such fabric to piercing by tightly weaving it or combining it layer-wise; hence hazardous substances can have no easy time in penetrating it.

This fabric also offers other functionalities vital for hazmat protection besides being puncture proof. In most cases, chemically coating or laminating this material makes it more difficult for various dangerous substances including acids solvents as well as corrosives to harm it. Thus, an extra coating serves as chemical resistance that enhances the extent of safety reducing any chances of exposure and guaranteeing the cloth’s soundness.

Moreover, strict safety standards and certifications must be met when designing such puncture-resistant fabrics. This includes industry-specific regulations and performance requirements where the fabrics undergo rough tests before being released into the market. Therefore, they supply dependable protection during hazmat conditions thereby giving confidence to employees who perform their responsibilities diligently.

Puncture-resistant fabric This is a special textile comprising some aramid or HDPE fibers. It has a good tensile strength and elasticity. It’s resistant to large forces, hence piercing objects like nails, splinters and thorns.

In addition to being strong, the puncture-resistant fabric offers high flexibility levels together with comfort. Furthermore, it is designed to be light in weight, flexible and breathable for easy movement as well as long term use. This is more vital in industries that require physical work by employees or dynamic situations.

Moreover, Puncture-resistant fabrics are also intended to meet particular industry standards and certifications. They go through a lot of testing done on them so that they can be sure they will match certain performance requirements which will make them reliable and effective enough for use.

Material selection is of great importance in determining the quality, duration and safety of outdoor adventure gear. Fabrics that are puncture-resistant resist sharp things, friction and cuts hence providing excellent protection to the user thus improving overall experience.

Outdoorsmen have a lot of obstacles in their way from rocky trails to thorn bushes, and unpredictable weather conditions. Puncture-resistant fabrics help guard against these risks thereby minimizing equipment damage as well as injury possibilities.

This fabric can be punctured by sharp objects without tearing. Whether in hiking boots, a backpack or a tent, this fabric provides strong defense against thorns, rocks, twigs and other potential sources of puncture injuries. By reducing the risk of gear breakage or tearing due to punctures, such a fabric allows participants in outdoor activities to become engrossed in their adventures rather than worrying about costly mending or replacement of spoilt tools.

Nize New Materials is one of the world's leading material suppliers. We have more than 20 years of experience in this field and serve customers around the world. We also have world-class production equipment and an annual production capacity of 5 meters of ionic sulfate.

We focus on the research of the anti-piercing shoe midsole, interrupting the monopoly position of the anti-piercing cloth midsole inforeian countries. and producing the anti-piercing cloth midsole of our own branc, filing the domestic gap

The factory covers an area of 83.5 mu and has more than 22.500 sauare meters of production plant, 3,000 square meters of research anddevelopment center, 3,000 sauare meters of office space and more than 500 sets of advanced production and inspection equipment

We have excellent products and a professional sales and technical team that can provide satisfactory solutions according to your needs. If you are interested in our products, we look forward to your online message or call for consultation!

Our products cover a variety of functional materials, whether they are waterproof materials, wear-resistant materials, flame-retardant materials or thermal insulation materials, which can meet the needs of different industries and applications.

Puncture-resistant fabric is a special textile material that provides protection against punctures, cuts and sharp objects. It effectively prevents the penetration of sharp objects such as nails, glass shards or metal shards, thereby reducing the risk of various injuries. Risk of injury in the industry.

Including puncture-resistant fabrics in PPE has several advantages. It provides an extra layer of protection without compromising comfort and flexibility. Puncture-resistant fabrics also reduce damage and tears, extending the life of PPE.

When selecting a puncture-resistant fabric, consideration should be given to the specific hazards present in the intended application, the required level of protection, comfort and flexibility requirements, durability and compliance with relevant industry standards, as well as the interaction between the fabric and other components of the protective system ( Compatibility of materials such as fasteners or reinforcements is also important.

Puncture-resistant fabrics can be made from a variety of materials, including high-performance fibers such as aramid (such as Kevlar®), polyethylene fibers (such as Dyneema®), and fiberglass or carbon fibers. These materials offer excellent strength and puncture resistance, making them suitable for protective applications.

Puncture-resistant fabrics can be combined with other protective properties to create multifunctional textiles. For example, fabrics can be designed to provide puncture resistance as well as flame retardancy, chemical resistance, or high visibility.