Tel: 0086769-23187408

Email: info@linzshoes.com

Tel: 0086769-23187408

Email: info@linzshoes.com

By incorporating flame retardant fabrics into protective gear, clothing, and machine covers, it significantly reduces the likelihood of burn injuries and potential fires, thereby enhancing workplace safety standards and compliance with industry regulations.

At refineries, drilling and natural gas processing plants, pipe-line situations, vaporized hydrocarbon and other inflammable substances continuously surround workers. The presence of exposed flames, sparks or even auto-ignition without adequate guarding can result into a catastrophic situation within no time. Flame-retardant fabrics mitigate these problems by preventing fire escalation and minimize injuries during accidents.

The flame retardant fabric resists flames, self-extinguishes when ignited and protects against high temperatures that meet industry standards such as NFPA 2112, EN ISO 11612 and ASTM F1506 among others. The garments made from these textiles include overalls, jackets, trousers as well as gloves that are essential to secure the workers in times of emergency.

In summary, this industry is developing advanced products that are fire resistant hence improving its vulnerability to fires and explosion which make safety critical for its economic sustainability.

Wherever there is fire danger, fire resistant textiles serve as tough and adaptable shields that can be used to increase safety. This pioneering textile technology has no limits and becomes a vital protective coating in many manufacturing industries, utilities, transport systems, hotels and public safety fields.

Flame retardant fabrics are created precisely to impede rapid flames spread that decreases heat transfer hence these materials remain tough as nails under harsh conditions. In this case, they do not ignite easily; they self-extinguish once ignited by flame and have been confirmed to comply with the recognized international benchmarks at failure of which a personal protective equipment (PPE) regarding fire protection cannot surpass.

These fabrics are also useful in other aspects like curtains for furniture, school furnishings and bedding in health care institutions hotels which have passive protection level from accidents due to fires. loss.

Today’s meaning of flame-retardant fabrics can be attributed to their adaptability as well as dependability. They are therefore adjustable to different environments but also retain the general level of fire protection while accommodating unique industrial needs. As such, they represent pro-active protection against unforeseeable hazards enhance preparedness culture and demonstrate commitment towards saving human life within any indoor environment where risks of burning remain persistent.

In high risk scenarios, flames from machinery, electrical arcs or chemical reactions can set alight flammable substances with deadly consequences but the use of fireproof materials in workwear enables employees to escape before they are placed in life-threatening conditions.

Flame retardant fabrics have been designed to prevent flames from spreading and reduce heat transmission when they come into contact with fire. Such fabrics contain new materials that can endure at very high temperatures, are non-inflammable and self-extinguishing, and meet strict global standards such as NFPA, EN ISO and ASTM.

Furthermore, the technology goes beyond protecting people’s clothing. Curtains, insulation blankets and other industrial applications integrate flame-resistant materials that act as passive fire protection systems inhibiting spread of fires whilst safeguarding critical infrastructure.

Although they are usually considering being strong and durable, flame- resistant clothes have developed some lighter alternatives for easy movement. These textiles maintain important fire-retardant qualities but cut extra mass using processes in advanced manufacturing and materials science.

Lightweight flame-retardant fabrics are essential in activities like firefighting gear, military uniforms or even sports wear for extreme events in order to enable users perform their duties efficiently. With improved agility and lesser fatigue, less bulk enhances operational functioning of people under intense conditions.

Nize New Materials is one of the world's leading material suppliers. We have more than 20 years of experience in this field and serve customers around the world. We also have world-class production equipment and an annual production capacity of 5 meters of ionic sulfate.

We focus on the research of the anti-piercing shoe midsole, interrupting the monopoly position of the anti-piercing cloth midsole inforeian countries. and producing the anti-piercing cloth midsole of our own branc, filing the domestic gap

The factory covers an area of 83.5 mu and has more than 22.500 sauare meters of production plant, 3,000 square meters of research anddevelopment center, 3,000 sauare meters of office space and more than 500 sets of advanced production and inspection equipment

We have excellent products and a professional sales and technical team that can provide satisfactory solutions according to your needs. If you are interested in our products, we look forward to your online message or call for consultation!

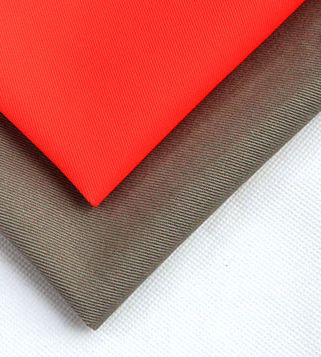

Our products cover a variety of functional materials, whether they are waterproof materials, wear-resistant materials, flame-retardant materials or thermal insulation materials, which can meet the needs of different industries and applications.

Flame-retardant fabrics are designed with comfort in mind. We use advanced technology in production to ensure that the fabric remains breathable, lightweight and flexible while providing flame retardancy. This allows for easier movement and reduces discomfort during prolonged wear.

Flame retardant fabrics can be used in a variety of industries, including fire protection, oil and gas, chemical processing, welding, power facilities and manufacturing. These industries involve environments where workers are exposed to potential fire hazards or work with flammable materials.

Flame retardant fabric possesses several key characteristics. These include its ability to resist ignition, self-extinguish when the flame source is removed, and limit the spread of flames. It also typically has a high melting point and low heat release rate to offer enhanced protection.

Flame retardant fabric can experience a reduction in its flame retardant properties over time, especially with regular use and exposure to factors like laundering, abrasion, and chemical exposure. It is essential to follow proper care and maintenance guidelines provided by the fabric manufacturer to ensure the longevity and effectiveness of the flame retardant properties. Regular inspections and retesting may also be necessary to ensure compliance with safety standards.

Proper care and maintenance are essential to preserve the flame retardant properties of the fabric. It is recommended to follow the manufacturer's instructions for cleaning, as some flame retardant fabrics may require special laundering techniques. Avoid using harsh chemicals or bleach that could compromise the flame retardant properties.

Flame retardant fabric is commonly used in a range of industries and applications, including the textile industry, the transportation industry (e.g., aviation and automotive), the building and construction industry, and in clothing and protective gear.