Țesătură Aramid: Materialul de Înaltă Performanță pe care Trebuie să-l Cunoști

Înţelegerea țesutului de aramida

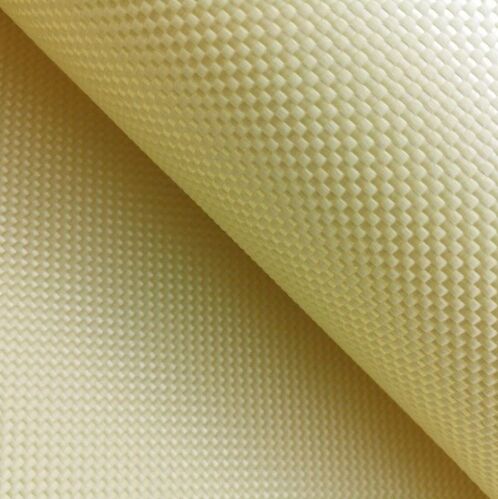

Fabrica de aramida este un tip specializat de fibră sintetică cunoscută pentru caracteristicile sale de performanță remarcabile, ceea ce o face esențială pentru îmbrăcămintea de protecție și diverse aplicații industriale. Aceste fibre oferă o rezistenţă remarcabilă, rezistenţă la căldură şi durabilitate, fiind ideale pentru mediile care necesită protecţie împotriva condiţiilor extreme. Industriile care folosesc adesea țesături din aramidă includ sectoarele aerospațiale, militare, de stingere a incendiilor și industriale, unde siguranța este de primă importanță.

Există două tipuri principale de fibre de aramid: para-aramid și meta-aramid, fiecare satisfacând nevoi și aplicații specifice. Para-aramida, cum ar fi Kevlar, este celebrată pentru rezistența și durabilitatea sa excepțională la tracțiune, utilizată în mod obișnuit în veste antiglonț și materiale aerospațiale întărite. În schimb, meta-aramidul, la fel ca Nomex, acordă prioritate rezistenței la căldură și flăcări, făcându-l indispensabil pentru echipamentul de stingere a incendiilor și pentru îmbrăcămintea de protecție termică. Fiecare tip de fibră de aramidă are proprietăți unice care îndeplinesc cerințele diverse ale industriilor cu riscuri mari.

Proprietăţile cheie ale ţesutului de aramidă

Fabrica de aramida este renumită pentru raportul excepțional de rezistență la greutate, ceea ce o face ideală pentru aplicații exigente, cum ar fi echipamentele balistice și rezistente la tăieturi. Acest material poate fi de cinci ori mai rezistent decât oţelul de aceeaşi greutate, oferind o protecţie incomparabilă. De exemplu, utilizarea sa în vestele antiglonț și cascotele ilustrează rolul său esențial în echipamentele de protecție personală, asigurând atât siguranța, cât și mobilitatea.

În plus, ţesătura de aramidă este rezistentă la căldură şi la flacără, ceea ce o face un material preferat pentru îmbrăcămintea rezistentă la foc. Anumite țesături din aramid pot rezista la temperaturi de până la 600 ° F, menținând integritatea fără topire sau picurare. Potrivit Asociaţiei Naţionale de Protecţie împotriva Incendiilor, rezistenţa sa la flacără o face esenţială pentru a fi folosită în echipamentele de stingere a incendiilor şi în îmbrăcămintea de siguranţă industrială, unde expunerea la temperaturi ridicate şi flăcări deschise este frecventă

În plus, materialul din aramid prezintă o rezistență chimică excelentă și o stabilitate dimensională. Aceste caracteristici asigură faptul că materialul rămâne intact în diferite condiții de mediu, ceea ce este vital în industrii precum aerospațial și auto, unde sunt necesare materiale durabile pentru a rezista mediilor dure. Capacitatea țesutului de aramidă de a-și menține proprietățile în timp îi sporește utilitatea în diferite aplicații, asigurând performanțe și fiabilitate de lungă durată.

Aplicaţii ale țesutului de aramidă

Fabrica de aramidă joacă un rol crucial în îmbrăcămintea de protecţie, în special pentru a proteja persoanele care lucrează în ocupaţii cu risc ridicat. Este folosit în mod obișnuit în costume de pompieri, veste de poliție și uniforme militare datorită combinației sale impresionante de rezistență și confort. Natura robustă a țesutului de aramidă asigură protecția maximă împotriva potențialelor pericole, în timp ce compoziția sa ușoară permite o ușurință de mișcare, o cerință critică în răspunsurile la situații de urgență.

Importanța țesutului depășește protecția personală și se extinde în diferite aplicații industriale, în special în sectoarele auto și aerospațial. Aramid este o componentă integrantă a fabricării anvelopelor și a componentelor aeronautice, ilustrând capacitatea sa de a funcționa în mod constant în condiții extreme. Natura sa ușoară, dar robustă, ajută la reducerea greutății totale a vehiculului, menținând în același timp integritatea structurală robustă, contribuind la performanța îmbunătățită și la eficiența combustibilului.

În plus, țesătura din aramidă este utilizată pe scară largă în scenarii de construcții și industriale datorită rezistenței și durabilității sale. Este adesea folosit pentru izolare și întărire în interiorul clădirilor, având în vedere rezistența aramidului la elemente dure și substanțe chimice. Această adaptabilitate asigură structurilor menținerea integrității lor în timp, reducând la minimum cerințele de întreținere, semnificând rolul indispensabil al aramidului în soluțiile moderne de inginerie.

Îngrijirea şi întreţinerea ţesutului din aramida

Pentru a păstra integritatea țesutului de aramidă, este esențial să se respecte reguli specifice de spălare și uscare. Spălați mașina cu apă rece și cu detergent ușor. Evitaţi amortitorii şi albiciul, deoarece aceştia pot afecta structura ţesutului. Uscarea trebuie efectuată fie prin uscare cu aer, fie cu o instalație cu căldură scăzută pe uscătorul de mașini. Căldura ridicată poate deteriora materialul, compromitând durabilitatea şi calităţile sale de protecţie.

Pentru menţinerea longevităţii materialelor din aramidă, este esenţial să fie depozitate în mod corespunzător. Păstraţi-le într-un loc rece şi uscat pentru a preveni acumularea de umezeală, care ar putea slăbi fibrele în timp. Evitaţi expunerea prelungită a materialelor din aramidă la lumina directă a soarelui, deoarece razele UV pot degrada materialul, reducând eficacitatea acestuia. Prin respectarea acestor recomandări de îngrijire și de depozitare, caracteristicile de protecție și durabilitate ale țesutului de aramidă pot fi păstrate, asigurând performanța sa continuă în aplicații exigente.

Produs în evidență: Țesături de aramida balistică UD

Țesăturile UD Ballistic Aramid sunt concepute pentru cei care caută protecție maximă fără a sacrifica confortul. Prin utilizarea unor materiale avansate, aceste țesături oferă un echilibru între construcția ușoară și siguranța pentru utilizări grele. Acestea sunt proiectate cu tehnologie de ultimă oră pentru a oferi o protecţie balistică excepţională, făcându-le o alegere ideală pentru mediile cu risc ridicat.

Caracteristicile cheie ale țesuturilor UD Ballistic Aramid includ rezistența la tracțiune ridicată, flexibilitatea și eficacitatea validată în protecția balistică. Aceste calități au fost testate riguros de către laboratoarele de conducere în materie de siguranță, asigurându-se fiabilitatea lor în situații critice.

Spectrul de aplicații al țesuturilor UD Ballistic Aramid este vast, deoarece sunt utilizate în echipamente de protecție esențiale, cum ar fi vestele antiglonț și vehiculele blindate. Rolul lor în asigurarea siguranței persoanelor și a vehiculelor nu poate fi exagerat, evidențiind importanța lor în domeniul soluțiilor de protecție.

Viitorul ţesutului din aramida

Industria de tesaturi din aramida este pregătită pentru progrese interesante, conduse de tehnologie şi inovaţie. Cercetătorii se concentrează pe îmbunătăţiri ale proceselor de fabricare care ar putea spori rezistenţa fibrelor şi, în acelaşi timp, să reducă costurile de producţie. Acest lucru promite nu numai țesături mai robuste, ci le face și viabile din punct de vedere economic pentru o gamă mai largă de aplicații. În plus, tehnologiile emergente deschid calea pentru metode de producție mai durabile, crescând astfel atracția țesuturilor din aramidă pe o piață conștientă de mediu.

- Inovaţii în industria de producţie : Inovaţiile tehnologice îmbunătăţesc procesele de producţie.

- Reducerea Costurilor : Aceste progrese fac ca producţia de ţesături din aramidă să fie mai rentabilă.

- Sustenabilitate : Noile metode promovează practici ecologice.

În plus, viitorul țesuturilor din aramid se extinde dincolo de aplicațiile tradiționale. Experții din industrie prevăd utilizări potențiale în sectoare precum tehnologia portabilă și materialele compuse avansate. Aceste țesături ar putea fi integrate cu dispozitive electronice pentru îmbrăcăminte inteligentă sau ar putea fi utilizate în materiale compuse ușoare și de înaltă rezistență pentru industria aerospațială și auto. Cercetarea și dezvoltarea continuă sunt esențiale, deoarece deschid noi oportunități pentru țesăturile din aramidă, menținând relevanța și extindând utilizarea sa.

- Tehnologia portabilă : Țesăturile din aramida ar putea deveni o componentă crucială în tehnologia portabilă.

- Compoziții avansate Se preconizează că acestea vor fi incorporate în materiale compuse.

- Dezvoltarea cercetării Cercetarea în curs este crucială pentru a debloca aceste aplicaţii potenţiale.

Întrebări frecvente

Pentru ce sunt folosite în mod obişnuit ţesăturile din aramidă?

Materialele din aramida sunt utilizate în mod obișnuit în îmbrăcămintea de protecție pentru aplicații de stingere a incendiilor, militare și polițienești, precum și în echipamentele de siguranță industriale, componente auto și aerospațiale.

Cum oferă ţesăturile din aramidă protecţie?

Materialele din aramida oferă protecţie datorită raportului remarcabil dintre rezistenţă şi greutate, rezistenţă la căldură şi flacără şi stabilitate chimică, făcându-le ideale pentru utilizarea în medii expuse unor condiţii extreme.

Poate țesăturile din aramidă să reziste la temperaturi ridicate?

Da, anumite materiale din aramid pot rezista la temperaturi de până la 600°F, menţinând integritatea fără a se topi, făcându-le potrivite pentru îmbrăcăminte rezistentă la foc.

Cum trebuie îngrijite ţesăturile din aramidă?

Țesăturile din aramidă trebuie spălate cu o mașină în ciclu ușor, cu apă rece și detergent ușor, evitând înmoașcătoarele de țesături și albiciul. Acestea trebuie uscate cu aer sau cu o căldură redusă pentru a-și păstra structura și eficacitatea.

RO

RO