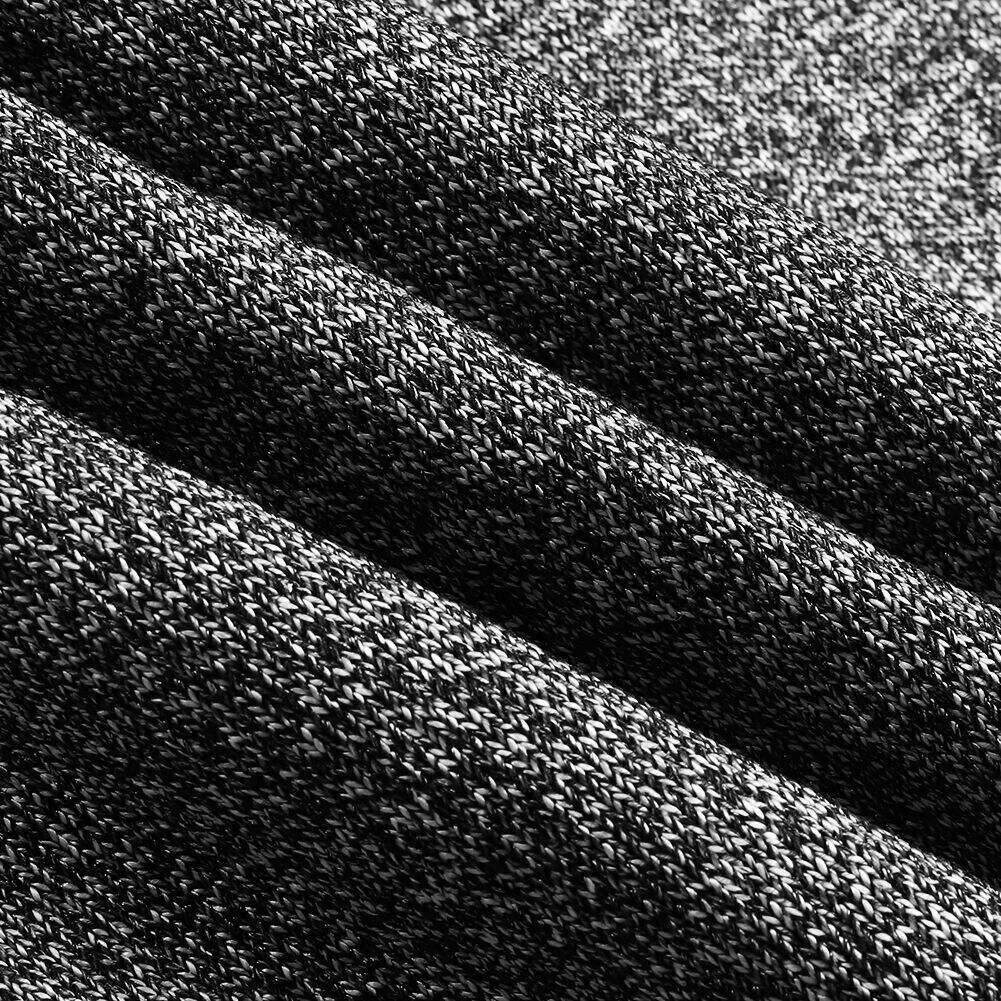

Cut Resistant Fabric for Personal Protective Equipment

One of the most significant innovations in personal protective equipment is Cut Resistant Fabric that protects workers from some of the most dangerous hazards. It was engineered to withstand forces that would have easily destroyed regular fabrics thereby providing a much higher level of protection against cuts and lacerations. Its impact on industries such as glass manufacturing and stainless steel production cannot be overemphasized, considering it shields against sharp objects that abound in day-to-day activities within these sectors.

Cutting strength is a principal feature that differentiates Cut Resistant Fabric from other materials. This fabric is made up of high performance fibers which are woven together enhancing their resistance to penetration unlike traditional textiles that can easily be compromised by blades among other fine-edged tools. The material has the ability to effectively resist cuts from different potentials sharp hard objects thus creating a safer working environment for those who handle hazardous materials daily.

Cut Resistant Fabric is mostly used in industries where hand and neck protection are very important. For instance, workers in glass factories are at risk of accidental contact with sharp-edged shards and fragments all the time. Similarly, stainless steel factories require employees to work with heavy-duty machinery capable of producing jagged metallic pieces. In these contexts, using Cut Resistant Fabric becomes not only advisable but also indispensable to avoid potentially serious injuries.

Its superiority doesn’t end there when it comes to cut resistance. It is also designed to be highly flexible and comfortable, enabling employees to move freely while meeting safety requirements as well. This comfortability arises from careful selection of raw materials as well as attention to detail during making processes which guarantee durability without compromising dexterity and mobility associated with various job duties.

Additionally, its durability allows the fabric go through industrial washing several times without getting damaged thus making it cost effective for companies needing long term safety clothing for their staffs. When worn out after lengthy periods of usage, it retains its protective capabilities thus providing a good return on investment.

Cut Resistant Fabric is a revolution in personal safety technology. Employing its exceptional cutting strength as well as flexibility, comfort and durability; it is an invaluable resource for industries where the risk of sharp object injuries remains high. In glass factories and stainless steel plants alike, this fabric helps to save workers from injuries hence demonstrating that material science can bridge productivity and safety. In this era of workplace health and safety, Cut Resistant Fabric demonstrates our capability to engineer lifesaving solutions for both lives and livelihoods.

EN

EN